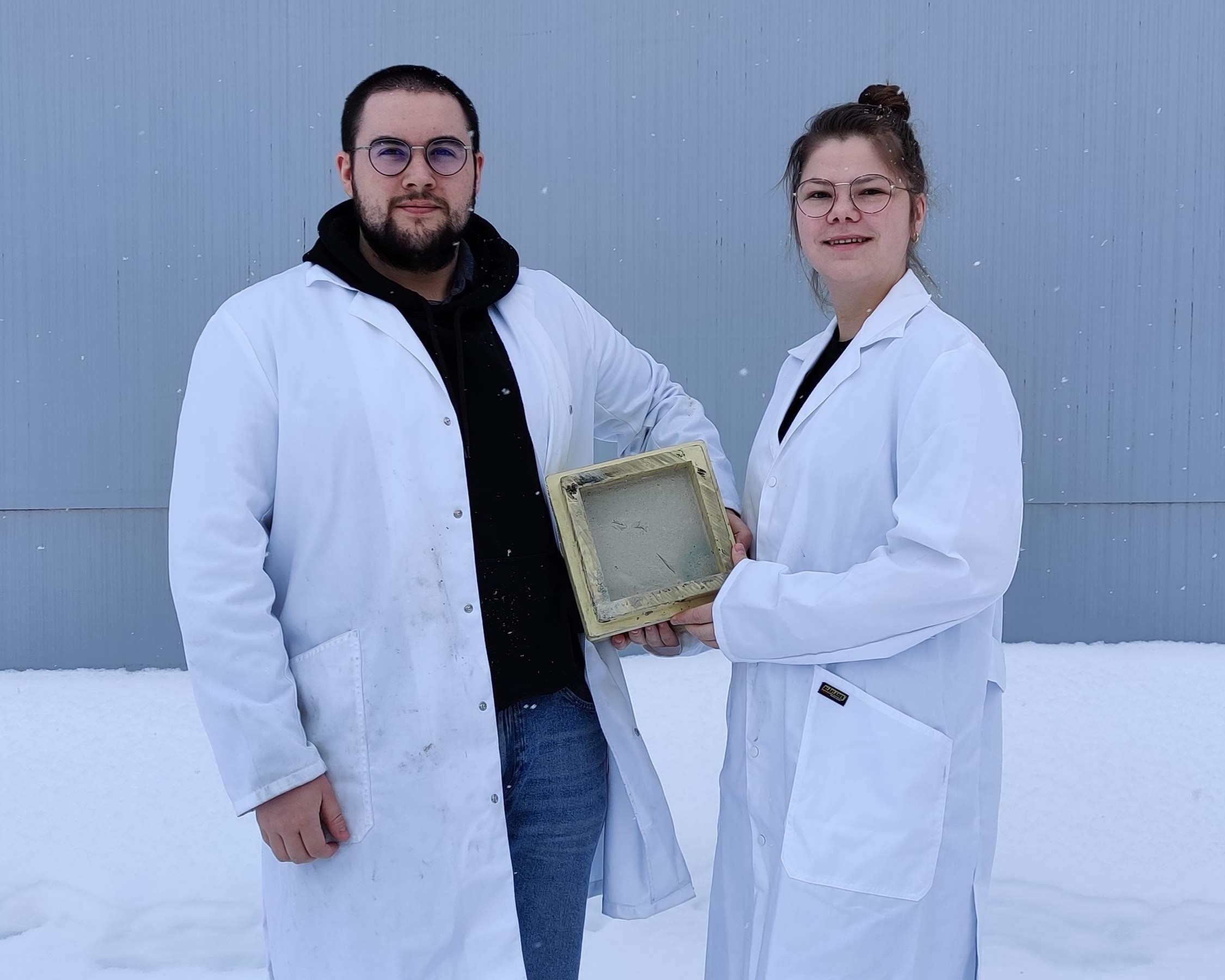

Master students Marie-Laure and Dario: Analysis of early-age properties of geopolymers with various waste materials

Geopolymers are one of the most advanced forms of concrete and mortar in this era. It is also an innovative and environmentally friendly building material compared to traditional cement-based alternatives, as they use mostly waste and industrial by products. The world of geopolymers is relatively young and unexplored, but has some deep roots in the past, as some, like Joseph Davidovits, who have dedicated their life to Geopolymer, made possible connections with the Egyptian pyramids, Tiwanaku and other ancient monuments.

Similar or even better properties than those of traditional cement-based building materials are obtained by reacting aluminate and silicate materials with an alkaline activator. It is no secret that some geopolymer mixes can achieve 70% of their final strength after only 4 hours of curing, but since there are still many question marks around geopolymers, many parameters and potentials remain unnoticed.

This research, carried out as a master thesis by Marie-Laure Heyndrickx and Dario De Muynck, exchange students from Ghent University (Belgium), focuses on the analysis of early-age properties of geopolymers with various waste materials. Firstly, an analysis is performed on local and easily available resources to have an idea of the possibilities regarding geopolymers with waste streams of Northern Norway. In the second stage, the early-strength development of a reference mix (0-24hrs and 28d) is monitored. Together with the evolution of mineralogy and microstructure, through XRD analysis, it will be possible to explain the changes in mechanical properties according to the changes in chemistry.

Finally, some alternative mixes are made with various waste materials and the same analysis is performed. The result of this research will offer the industry and fellow researchers knowledge on the use of different waste materials and their impact on the final product. It also promotes the use of these waste materials as they can make up to 85% of the total weight of a geopolymer, a big step towards a more sustainable future.