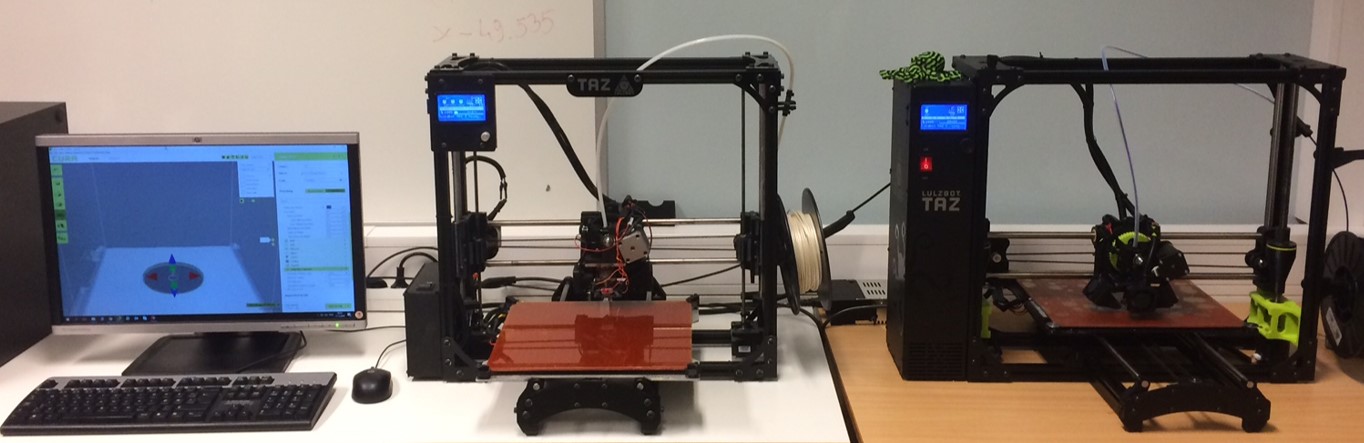

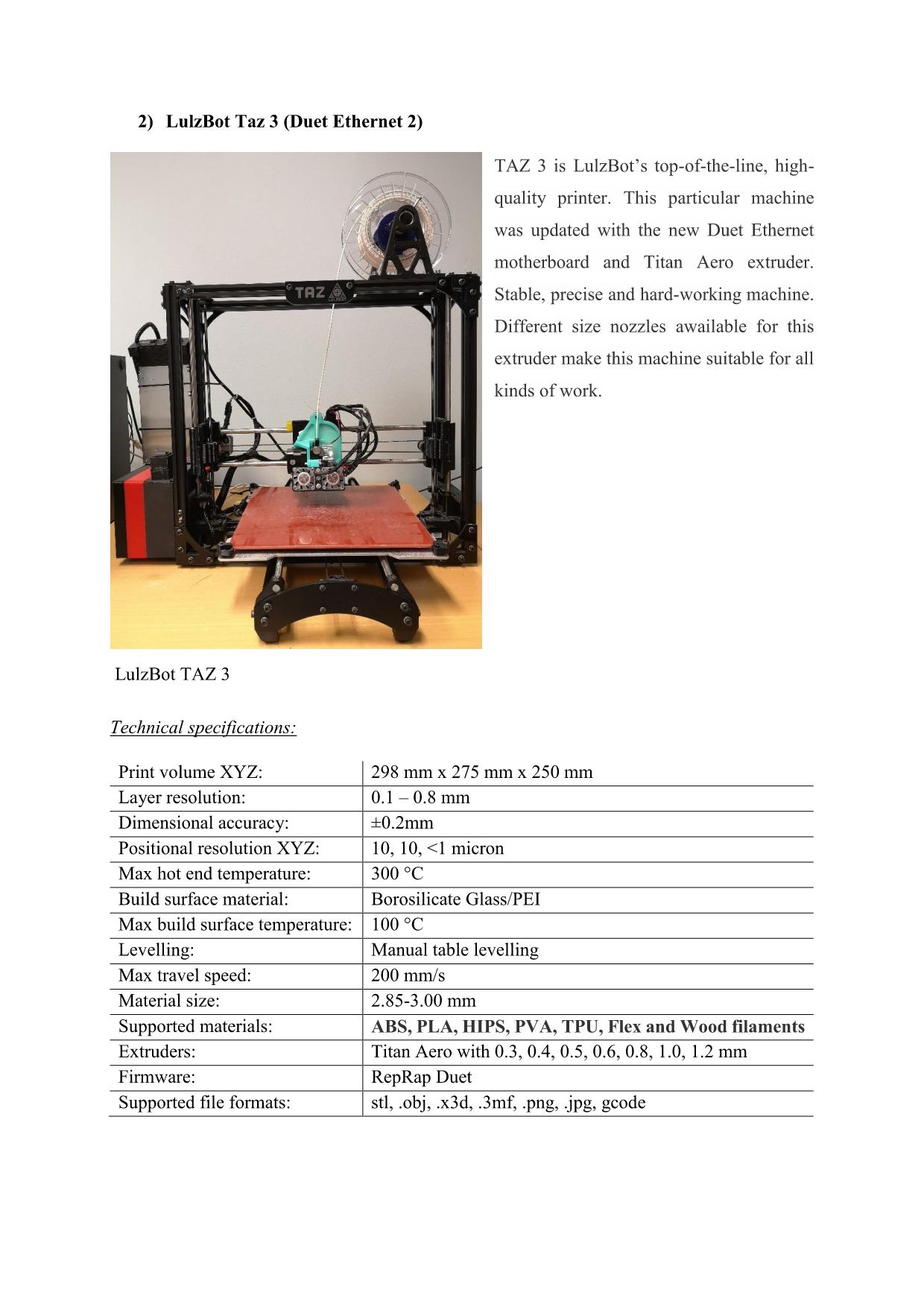

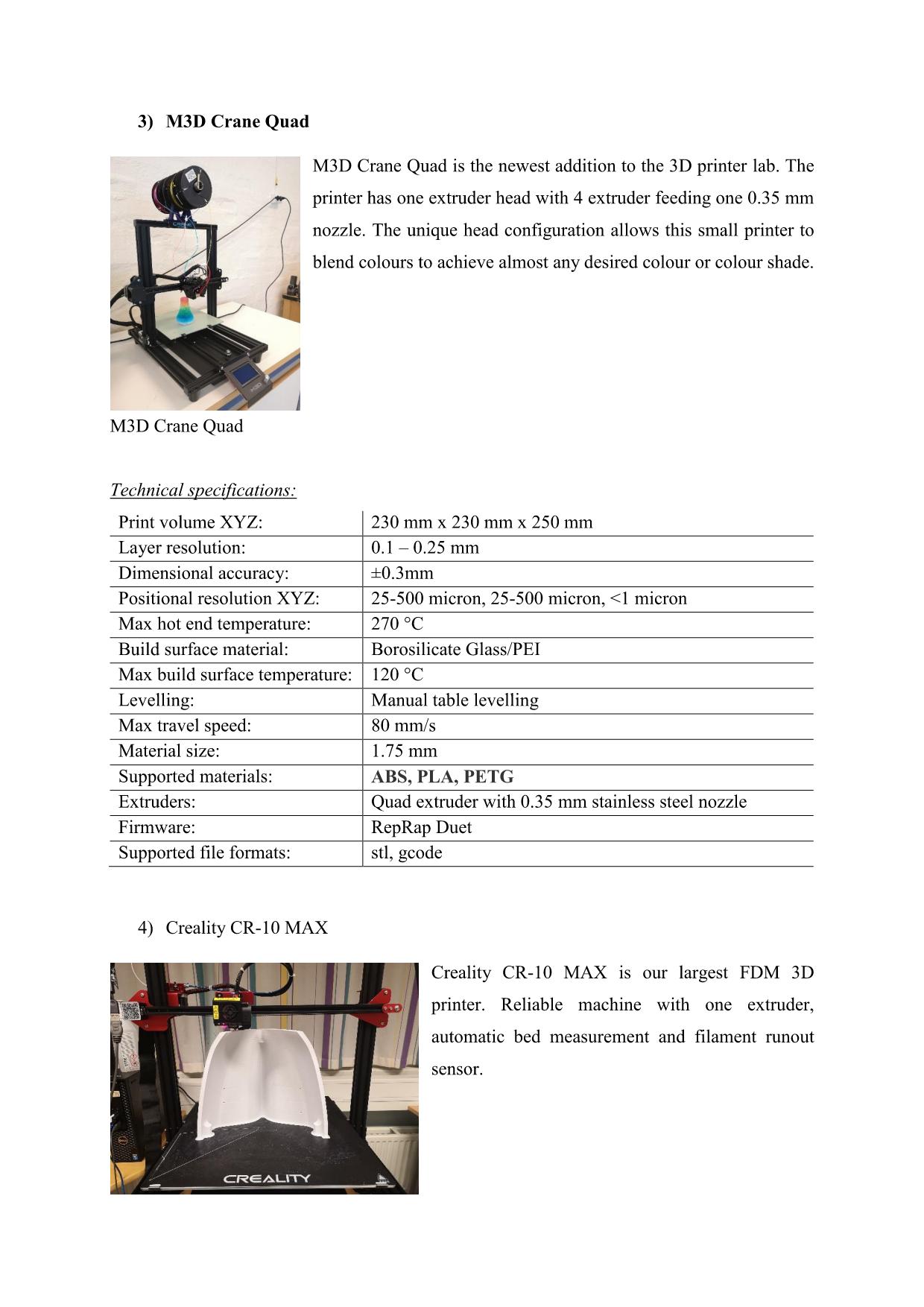

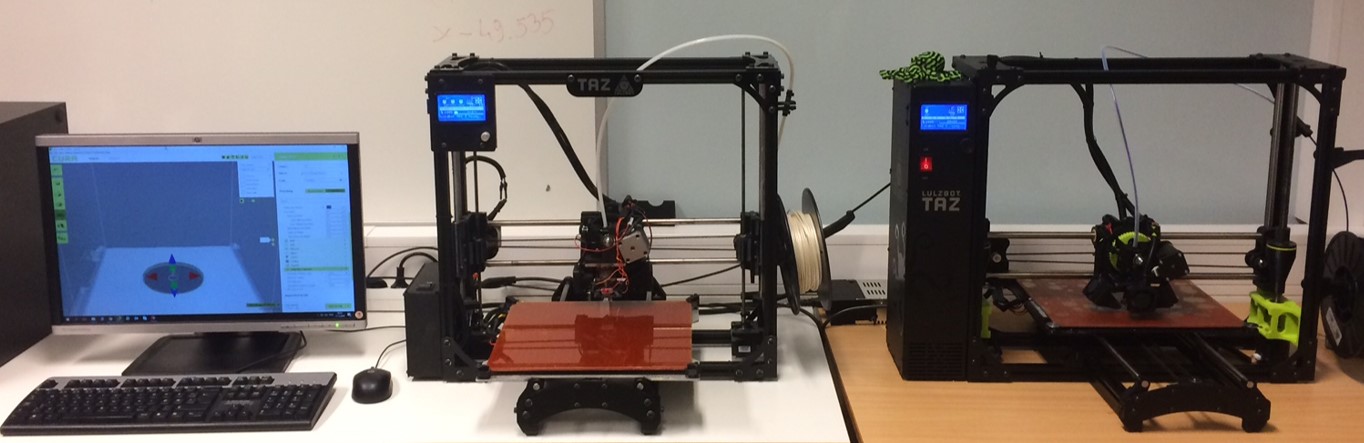

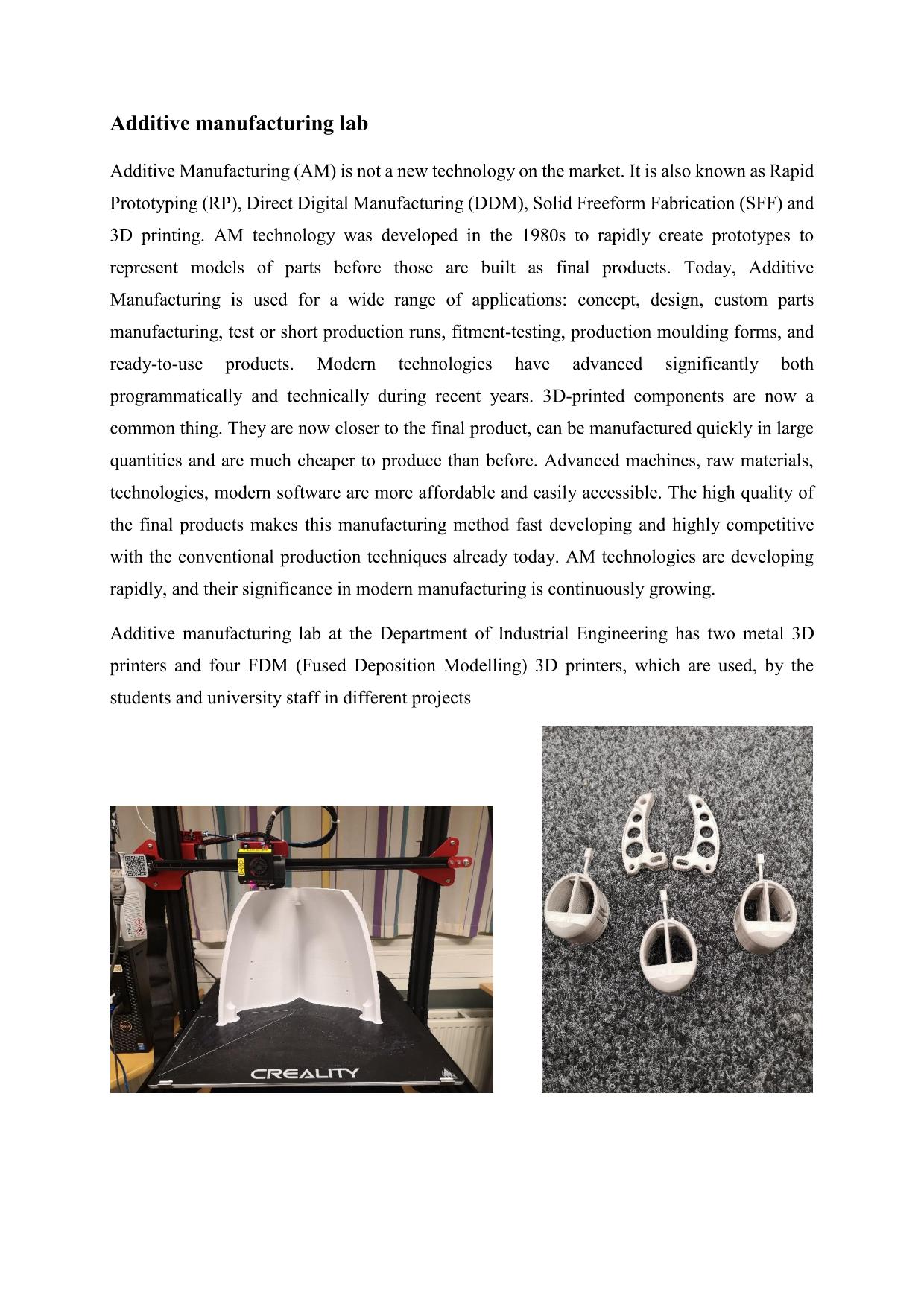

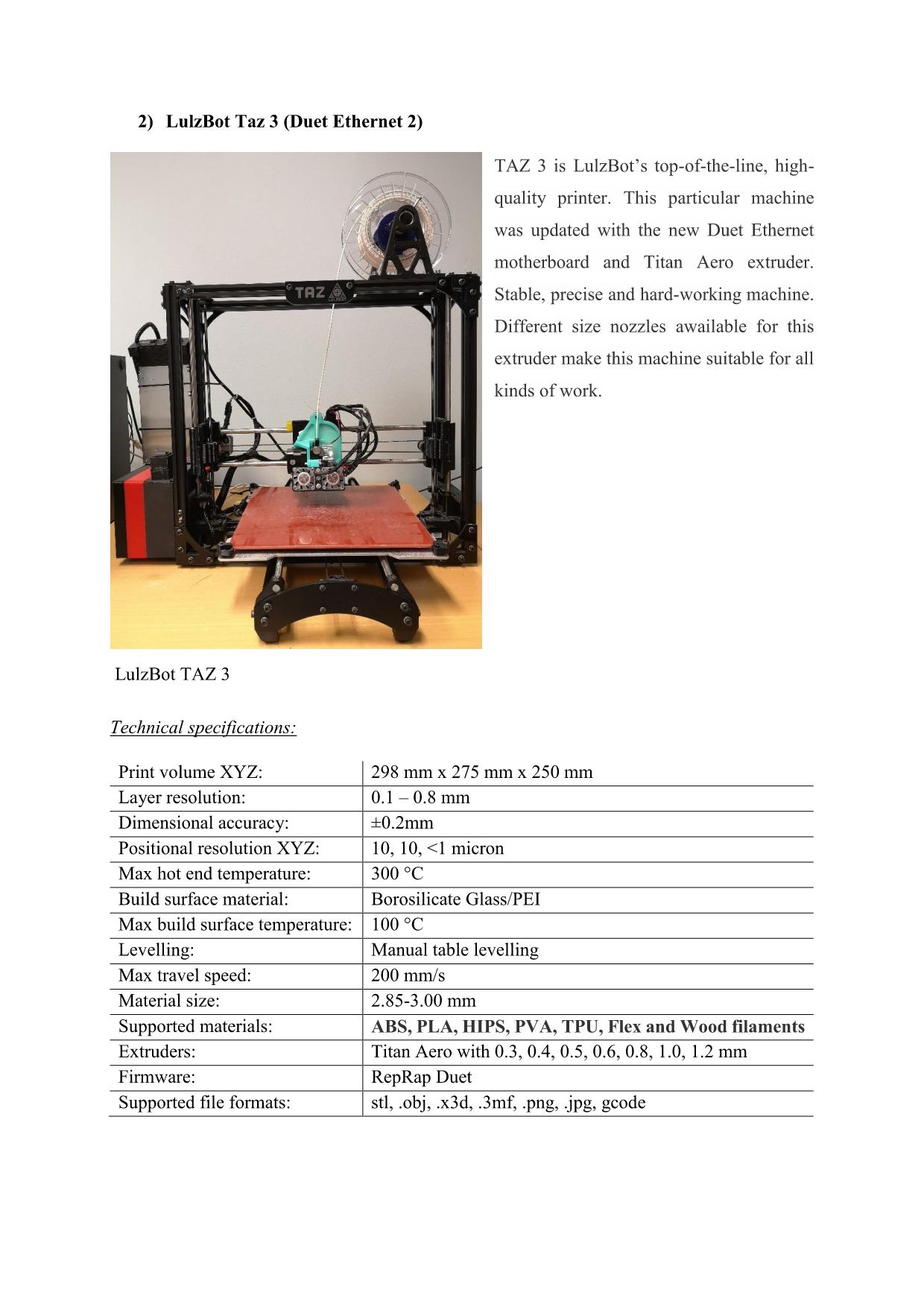

Laboratoriet er utstyrt med to 3D printere som benyttes til å lære studenter prinsippene med plast 3D printing. Fakultetet har også en rekke andre 3D printere i Narvik (lenke).

Kontaktinformasjon

Øyvind Søraas

Sideansvarlig: Søraas, Øyvind

Laboratoriet er utstyrt med to 3D printere som benyttes til å lære studenter prinsippene med plast 3D printing. Fakultetet har også en rekke andre 3D printere i Narvik (lenke).

Øyvind Søraas