The introduction of synthetic fibres, such as those made of polyamide (PA6 or nylon), in the late 1950s was a technological improvement that increased fishing capacity and the economic viability of fisheries worldwide. Gillnets produced of synthetic materials are durable and have a high tensile strength. Unfortunately, they happen to get lost, abandoned, and/or discarded in many important fishing areas.

The impacts of this include ghost fishing, changes to the benthic environment, marine plastic pollution, navigational hazards, beach debris/litter, introduction of synthetic material into the marine food web, a variety of costs related to clean-up operations, and impacts on business activities. The problem increased significantly with the introduction of synthetic fibres and the following increase in fishing activities. As a replacement for traditional nylon (PA) gillnets, biodegradable gillnets that can be completely degraded by naturally occurring microorganisms in seawater have been increasingly discussed and researched in recent years. The fishing efficiency of these gears made of biodegradable polymers is in some cases comparable to gears made of polyamide (PA), polyethylene (PE) and polypropylene (PP).

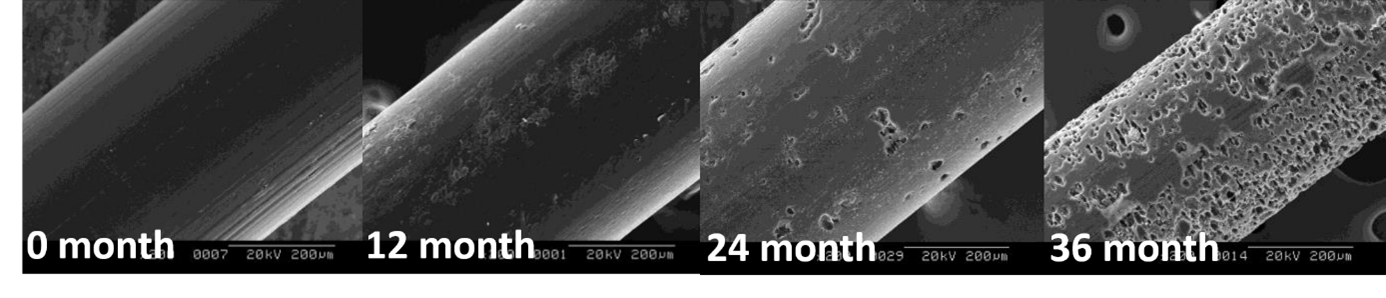

Initial studies have shown that biodegradable nets have similar mechanical properties during fishing, but that they can be completely degraded in seawater when left in the marine environment (see figure below). However, there is still a great need for research to improve the mechanical properties, fishing efficiency and biodegradability of these gillnets and other equipment which are interesting for future applications.

Natural bacterial strains degrade PBS monofilaments (polybutylene succinate, degradable plastics) into H2O (water) and CO2 through an anaerobic digestion process (source: S-ENPOL)

The degradation process

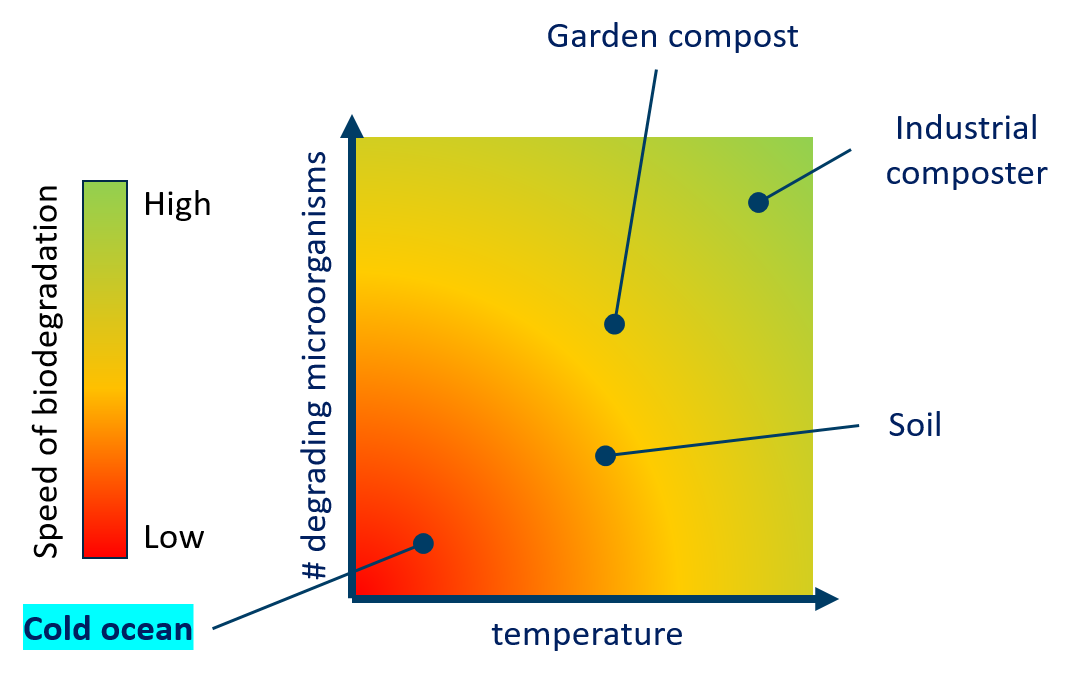

Environmental factors such as exposure to UV radiation, oxygen, heat, wind, waves, seawater, and bacteria all influence the degradation of synthetic materials in the environment. This degradation process leads to significant changes in the chemical-physical and mechanical properties of the polymer. The impact of these factors leads to cracks, surface erosion and abrasion of the material, which further leads to its disintegration into macro-, micro-, and nano-sized plastic pieces. Biodegradation, as part of this degradation process, is based on chemical-biological processes induced by the interaction of the surface of the polymer with enzymes secreted by microorganisms, such as bacteria and fungi. In this process, the polymer molecular weight is reduced by shortening the polymer chains and cleaving off molecular fragments, which then can be digested by the microorganisms. The rate of biodegradation depends strongly on the environmental conditions, such as temperature and number of suitable microorganisms (see figure below). The marine environment has one of the most difficult conditions for biodegradation as there are generally low temperatures and small numbers of suitable microorganisms.

(Source: Stephan Kubowicz, SINTEF Industry)